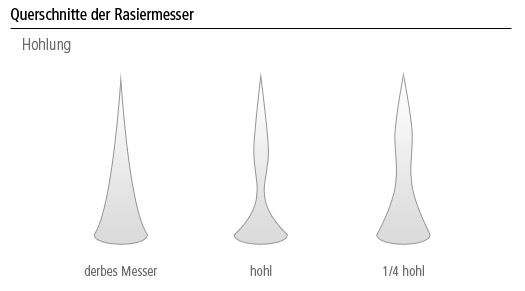

The grind

Grinding a razor blade is a supreme art. This is where the wheat separates from the chaff, and precisely the reason why Solinger razor blade blacksmiths excel.

The fabrication of a razor blade takes estimately 140 working steps, but it"™s the grinding that makes the quality of the work of Solinger professionals visible. 20 of those steps are connected to grinding only.

Zwickmeister solely offers razor blades on the highest quality level with a full or extra hollow grind. A grind, that can only be produced by manual work, and takes years in experience to perfect.

Only razor blades being treated with such a hollow grind will survive the ultimate test - pressing the blade on a thumbnail for it to bend.

For a blade, that is flexible, will adjust to the skin and enable the razor blade its sharpness and durability.

But Solingen razor blades aren"™t only grinded to be especially sharp (through fine grind), but also treated with a "Blaupließ" grind: The surface is grinded so smoothly, that it develops a nice matte finish, for that the steel provides less points for corrosion or similar environmental impacts.